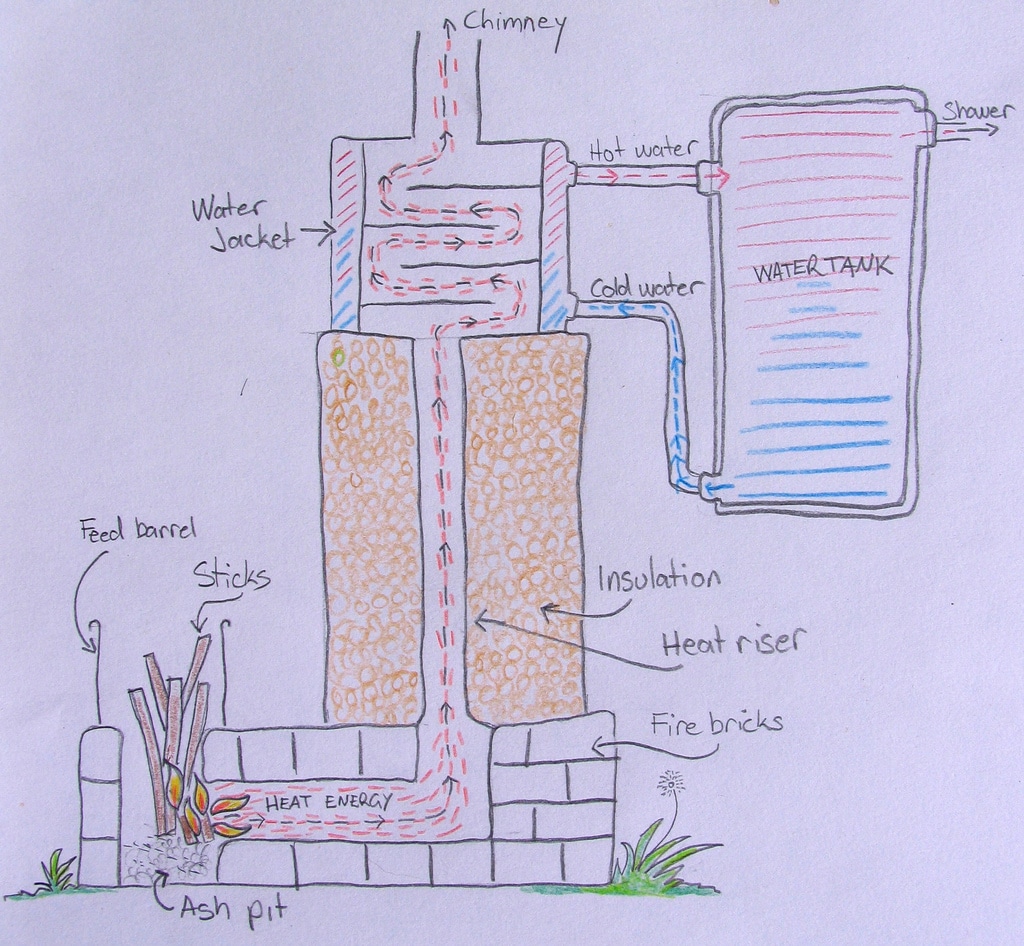

Rocket stoves are awesome, experimental, and a knowledge stream in flux. Or ours is, at any rate. Our rocket stove water heater has been doing its thing for nearly 3 years now, so we decided to take it apart and do a full examination of how it had fared.

So Nick and our current permaculture interns set to work completely dis-mantling the rocket stove water heater and examining all its components. We made new discoveries and adjustments, put it all back together, and then covered the whole thing with mud.

The rocket stove water heater prior to redux, after 2.5 years hard labour. Working, but not as well as it might.

For a short history on our much beloved rocket stove water heater, see the original article here and our 2.5 year assessment here. This setup has definitely done good service, but it wasn’t functioning as efficiently as it used to. Time to see what was going on.

After taking the heat riser and the water jacket off, two things became clear. The first was that the vermiculite that we used as insulation in the heat riser had settled, leaving a 10cm gap at the top of the heat riser chamber. So that was decreasing the efficiency of heat transfer.

We chose to switch from vermiculite (which would continue to settle over time) to some left over earthwool insulation we had left over from the tinyhouse build. As earthwool is made from spun rock, it’s a good choice as it won’t burn or shift under the temperatures employed in our rocket stove.

Installing earthwool into the heat riser. Non-settling insulation that won’t burn, made from offcuts of another project.

The second thing we looked at was the water jacket heat exchanger. The internals of it were filthy. While you would expect any chimney to be filthy (in a wholesomely sooty way), there was so much creosote build-up on the walls that we could scrub it off in massive flakes.

This meant that there was a thick layer of stuff between the hot air from the fire and the metal lining in which the water waited to be heated. Which is not what you want for efficient hot-air-to-hot-water transfer. So we scrubbed it out.

This creosote is coming from the eucalyptus sticks we burn in the rocket stove. It’s a natural byproduct that you’re going to have to live with, if your available wood source contains large amounts of it. So until we get our super year-round-willow-coppice-sapling-stickwood supply sorted, we’ve got lots of creosote. Fair enough.

Once we’d cleaned everything out, we made a couple of other small improvements, one of which involved sacrificing one of my salvaged stainless steel bucket-things for a new and improved feed chamber surround.

I wasn’t entirely happy about this but i suppose all those future hot showers will be worth it.

Then it was time to cob. We had previously cobbed around the firebricks and feed barrel, but due to inadequate roofing (long since fixed) the cob eroded early in our rocket stove’s life. Now it was time to get serious. A layer of cob from top to tail, all in the name of mud.

All finished and time to fire it up for a nice hot shower. And our rocket stove water heater worked! Much better than it had for a long time previously! Huzzah!

Finally, i think the creosote issue is something that we’ll just have to address on a yearly or bi-yearly basis. I’m ok with that, especially as this is an outdoor, experimental system, and so we may be looking at breaking down the system every 1-2 years to clean it.

Hey, two years of zero-footprint hot showers for one day of tinkering and slapping mud on stuff? Sounds ok with me.

Thanks to our fabulous interns for doing a great job on this project and for taking so many silly pictures of each other smeared in soot and mud. Cheers to Adam, Olivier and Claire for the pictures.

Rocket Stove resources:

Possibly related posts

- Our rocket stove water heater: 2.5 years on

- The rocket powered shower

- Mud, glorious mud: rendering the tinyhouse

- Compost toilet specifics: the wheelie bins

Fantastic, I’ve always wondered how rocket stoves work – thanks for sharing the pics and info 🙂

you’re welcome. They’re great fun and quite easy to get going on as a project…

Great Job!

If you somehow cover the heat exchanger witha layer of dense ceramics fireclay) you could lessen the creosot condensation. By this height of flame not all burnable gases are burned. Maybe if aoid such premature contrast between metal water and fire…

Peace and prosperity !

thanks for the tip, Martin! Will look at that…

We are living in geodesic design yurt in Montana. We built it from thinning slash, discarded bill board tarps and rigid insulation. We are heating it with a rocket hybrid stove. We never could get it to work correctly as a down draft system. I suspect that the long, radiant heat floor, run is the problem. We built a small burn box that works well burning horizontally. The down side is that we need a fan to pull rather then the draft pushing on its own. The up side is that the mass is working well as a heat battery.… Read more »

Can you give us the sizes of the drums that you have used to make the rocket stove. Winter is on its way and we want to make one at the Himalayan Farm Project.

Sure – the heat riser is a standard 44 gallon drum (used world-wide) and the heat exchanger is approx 30cm cubed. Any metal worker could whip you up one, they’re very simple devices. The feed chamber is about 20cm in diameter at the top, and about 30cm top to bottom. The firebricks used were just standard insulating firebricks (you could use DIY sawdust/cement combo bricks also) and the chimney is about 1.5m tall above the heat exchanger… good luck! Lots more links to rocket stove plans of all shapes and sizes here: https://www.milkwood.net/2011/06/14/rocket-stove-roundup/

Hey if you use red lava,and wet it,roll in powdered clay,then mix it in a mix of sawdust and clay 3/ 1 you can have a cob insulation that is fireproof,effective

and much more permie than this old world worm killing lung cancer causing rock wool,fiberglass,and perlite.

As you may have noticed ,cob projects often like to be cut up and re designed,usually with kids and pets around PLEASE consider staying away from the dangerous irritants.they cause permanent,irreparable damage to both the environment,and you.

Nico California cob educator

Hi Nico, yep we hear you, but as we already had the material on-farm, and everyone was very well protected during it’s install, we still think the earthwool was a good call. the heat rise barrel is capped at top and bottom independent of the rest of the system so no need to re-jig the earthwool aspect of this system in the future. we’re always learning new and better ways of doing things here, but we also work with our available resources, in order to make sure things keep moving forwards in a timely fashion… any links to this fireproof… Read more »

Don’t understand the problem here, Nico.

Can you re-phrase, please, in reference to this project at Milkwood?

Is the cob used here is a problem or is the earthwool product a problem?

I think Nicofrog is saying that a lava/cob combo would be more ideal as an insulator (from a footprint and potential safety when installing) perspective in the head riser than earthwool. Which i agree with, but we had leftover earthwool on site at the time and no red lava (which would need to be imported, and also still needs to be mined), and we were very careful during the install of this aspect of our system (earthwool (spun rock) has small particulates which need to be considered). But a great ide and once that we’ll look at in the future… Read more »

Don’t understand the problem here, Nico. Can you re-phrase, please, in reference to this project at Milkwood? Is the cob used here is a problem or is the earthwool product a problem? Ok I’m regretting posting here, ther is NO problem,Natural building is FUN I don’t want to Debate anything with anyone I have been a potter for 60 years and a natural builder for 12 all I was saying is there are alternative insulation materials to Rock wool,fiberglass,and perlite. which are all energy intensive to create and available used for sure,but the dust is pervasive and harmful. the heater… Read more »

No the clay and sawdust just acts as filler/morter for the red lava,which is quite adequately insulating.I use this on cob ovens

we used ashes in one rocket stove,but they tend to compact..

the clay is minimal

Just enough to act as glue…Nico

yes we’d heard that ashes tend to settle, hence why we didn’t use them for insulation (tho I love the immediacy of using ashes in a rocket stove for insulation). Cheers for the lava idea – will keep it in mind.

Please excuse my cold water but … there are several misconceptions here. Rockwool, resined fibreglass (and fibreglass per se), as well as perlite have never been attributed with lung cancer (particularly rockwool) … unlike asbestos (and asbestosis) … though it is wise to minimize the inhalation of any small non-biodegradable fibre, for obvious reasons. Secondly … this is not ZERO FOOTPRINT! This system releases CO2 as a by-product just like any bushfire, which is taken into account by the government calculations for CARBON EMISSIONS. It is close to zero cost though (provided you have fuel trees nearby) and duplicates the… Read more »

Thanks for your points Daniel. No need to shout tho..

We’re not trying to re-invent the wheel, we’re just describing the system that heats our water, and which works for us. I do agree that this system is not zero footprint per se, but in comparison to fossil fuel based water heating alternatives, I think it’s pretty darn responsible and appropriate for our particular situation, which is what I was trying to get at.

Best, k.

This is an old post I just started reading through. Thought I might as well comment though. CO2 is released out of the sticks as they decompose. As far as I have researched, if you burn wood from your property. ie: not transported by fossil fuels. and you burn it hot and clean. This would mean that you would have minimum creosote build up if burned hot and you burn the gasses as well as the fuel). Then the result is really not as far from carbon neutral as you are saying. The CO2 that was to be released over… Read more »

Hi Daniel; thanks for your intelligence on the subject,I never mentioned cancer; Its enough for me that worms hate the stuff. and if you want your Kids breathing Glass Rock fiber or perlite.that your choice, the occupational hazard folks have pretty good readouts on the hazards of kiln fired material in Lung tissue. the microscopic forms of red lave are courser,and don’t tend to lacerate tissue,look at microscopic photos of fiberglass and perlite. as to footprint issues, lobby against S.U.V.s and enjoy burning wood. or sit around watching Hollywood blow everything to bits on t.v. and wonder why you worried… Read more »

Hi everyone, I think you’ve missed the point, even if I didn’t state it explicitly. The type of insulation isn’t the issue. Small black poly-pipe (over a good area) exposed to the sun or reflector type water heaters (aluminium foil wall-papered over paper-mache or fired mud, formed in a satellite reflector or a continuously curved section or similar) can be constructed for next to nothing and using rockwool, pearlite, or fibre-glass for the holding tank insulation is far more superior (though significantly ‘hot water’ is only available after a few hours of radiant heating). It is considerably more innovative (particularly… Read more »

Daniel, thinking back to your last shower, how was that water heated? Would you share that info? this is a site about our farm, and what we do here. The rocket stove works for us. The insulation was surplus and better to use than to leave in a shed (in my opinion). We get ‘significantly hot water’ from this system after 20-30 minutes under normal conditions, not hours and hours. Right now as I speak, we’ve had 4 days of rain and 40+ people showering here on a daily basis. The rocket stove is a good solution for our needs… Read more »

Daniel: OH whomever you are right right right and I am wrong wrong wrong,I’ll bet you win a lot of debates! weeee bye N

Great Job!

I just wonder…if you take a pot with i.e. about five litters of water, heat it above a fire and take a shower or use it to do the washing…wouldn’t it be the same? or are you using the water to heat up the house?

Not trying to put down your job at all.

Fantastic and beautifull design.

jose

I love this rocket stove design and have been following its fortunes for a while. I’m planning something similar for our winter bathroom water heating. I was intrigued – though also more than a little apprehensive – at the use of earth/rockwool insulation. Not for any of the reasons in the comments above, but because despite it being rated to withstand high temperatures, my experience with it in these situations hasn’t been too promising. I’ve used it to create a stove-top oven for a cast iron woodstove: it surrounds a large aluminium saucepan encased in a strong cardboard box which… Read more »

Do you have to pump the water through the heater or is convection enough to fill the tank with hot water. Nice work. Thanks for posting. I am working on a rocket stove brewery and considering replacing my water heater.

Hi Bob, convection does the job – no pumps involved in this system… all the best with your projects

hey guys, great ideas. i really need more info on the construction phase of the water heat exchanger unit. i was also wondering if you could maybe have used a small(10-20 gallon), water heater tank as your exchanger? just a thought. keep up the good work.

About the creosote build-up; the thicker the layer the poorer the heat transfer and the hotter the outer layer creosote gets. At a certain point it will catch fire and flake off on its own in the process.

The fact that it you lasted 3 years unattended and still functioned seems to indicate that it it is not deserving of attention and is probably self-regulating.

Hello, I have found that you really do not need the heat riser in a vertical flue setup, My unit is firebrick 3diameters high below the heat exchanger, and I still have a damper in the chimney to prevent overdraught, the height between the fuel feed hole and flue outlet must be over half a metre

great design. thanks so much. My question: I understand the convection flow of the cooler water out the bottom of the tank to the heat exchanger and back to the tank. The part I am missing is how do you get the water from the tank to the shower head? Is your whole system pressurized like a traditional home? do you have any ideas how to accomplish a similar design without a pressurized system?

hey kyle, the water is gravity fed from a header tank up the hill so there’s gravity fed pressure. Mm not sure who you’d do it otherwise but i’m sure a little research would reveal a solution?

thanks, that is what i suspoected. without overall system pressure, i guess i would have to perhaps use an airpump to pressurize the tank, or hand pump hot water into a bucket over my head. its all good.

Amazing construction, and highly efficient it appears.

Just to lower the tone a little though – does it ever get mistaken for a high back W.C.?

Ha! Not as yet, thanks to our education programs 🙂

This is a very good straight forward idea. I’d like to use it for an outdoor bathtub since I love to soak. I think the tub could be filled cold and recirculate just like your tank. Question: That water jacket. You mention that you got it at a garage sale. Was is hand made or can you buy one?? Any way to know how to size it???

Have you guys considered making your own charcoal for use in the rocket stove ? Burning charcoal should eliminate deposited creosote, resins and a lot of soot inside the stove. It will also cut down on smoke.

Derek

Hi guys. I am very interested in building this type of rocket stove water heater but am still puzzled at how to make the water jackets as i cant get it locally in my country. please advise. thanks. hope

Following Hope question a drawing with size and dimensions of the water heater would help.

Also, I would like to know where does the cold water enter the system ?

is it at the water heater or at the water reservoir ?

JP

Hi Kirsten,

I’ve got an observation/question. Won’t you have less problems with creosote in your heat exchanger if you create a gap between the burn chamber and the heat riser, to introduce some fresh oxygen so all those nice hot gasses can combust? That’s the feeling I’m getting when I’m looking at your setup. There’s a lot of heat, but also a lot of unburnt gasses (that creosote is just unburnt fuel) and if you introduce some oxygen at that point, I reckon you’ll get an ever bigger heat return, and in the long run less problems with the creosote.

Badger Your point is well taken. I have an older Vermont Castings wood stove with a catalytic burner in the top. Have to wait for temp to get hot enough(400 degrees F) to ignite the fire byproducts(smoke) but then the stove top will climb to 1100 to 1200 degrees F. the stove has a second air inlet with a screw disk to close to the inlet down. A little adjusting initially was the only time it has been adjusted and the opening is small-small-small.

Can you help ? I built a rocket wood heating fire, followed all the direction, or believe I did. But when you lite it, has a back draft, but then fills the room with smoke. I know this is a shot in the dark and asking a lot without seeing it. We moved the fire box as close as well could, seems to have the right clearance at the top of the drum, which we cut down in the end, but know change at all. We are stumped. Any ideas ? Appreciate any help. Kind Regards Brian

Okay, Ripping it out tomorrow and going back to a slow combustion wood heater. Thank you anyhow.

I am happy to do construction drawings of the heat exchanger, just give me some overall sizes.

Kind regards Joe

Reblogged this on Off Gridders and commented:

Here an excellent little rocket stove water heater…. any big city apartment design are welcome please.

My Hot Water heating system has now been running for 1.5 months, 1 fire a day, to raised 180litres from 30 to 57 degrees Celcius. Time taken to reach that temp an hour. fire lighting is very easy. my system is a square section stoking hole and burn tunnel 120mm, the heat riser is a continuation of this vertically of another 240mm,(all fireproof concrete, and insulated a thickness of 50mm with rockwool) it then flares out to become a seat for the heat exchanger 200dia, and 300 long with 8 fue tubes in it(made of mild steel). followed by a… Read more »

Have u heard of the old Aussie chip heater? Copper coil in a drum. Hot water in 3 minutes. Right beside the shower so if it cools down feed more twigs and away it goes. Works like an ice bath beer keg cooler in reverse.

you would get a better thermosyphonic effect if you had the cold return water going straight into the tank and the hot primary flow going up to the top of the water chamber. Probably you can just swap the pipes over and adjust height of tank? Cold water does not ave much power to move easily as it is denser, hot water flows easily and wants to climb!

Great design! I’d love to replicate it. However, there are many people out there in the permaculture world who caution against heating water with a rocket stove saying that you could “blow up your house” etc. Probably a valid concern, but would you please share why you think THIS UNIT does NOT explode and shed light on the subject for the paranoid permies out there? Thanks!

Er, it wont blow up because it’s got a release valve on the water tank. Just like any electric or gas water heater.

for safety’s sake, fit an open vent pipe to the top of the cylinder, I would not rely on a mechanical pressure relief valve and an open vent just another pipe. As I said before, make the cold water pipes level and the hot pipe rising up.

Rocket stoves are a great concept but situations where you want an intense burn are limited?

great idea, here is other great idea to heat the pool https://www.patriotdirect.org/how-to-heat-a-pool-with-solar-energy/

Why do people use cob? What is the purpose, the principles that make it necessary, for which I could find a replacement? I live in Canada, and in my area, straw and clay aren’t part of the area’s natural production, and I imagine that a mud derivative would not survive our reasonably high precipitation rate and winters. What could be used as an alternative?

HI looking at the drawing and having a outdoor “boiler”water heater[woodsmaster 5500] and having built large air-air [multi-million btu size heat ex changers] some things puzzle me as to why you have chosen to reduce the heat available to heat the water without some other use for it. The insulated barrel above the fire is simply a heat sink that seems to serve no real purpose other than lifting the heat ex changer/creosote chamber up to a convenient height for the water tank. The heat exchanger is always a problem with the water on one side of the metal and… Read more »

thanks for your thoughts! We haven’t been at this farm (or using this system) for quite a few years now – but you never know where life will take you and if we DO make another one of these I will be super thankful for your input 🙂